Can we burn metal for heat, instead of fossil fuels?

Try burning an iron metal ingot and you’ll have to wait a long time — but grind it into a powder and it will readily burst into flames. That’s how sparklers work: metal dust burning in a beautiful display of light and heat. But could we burn iron for more than fun? Could this simple material become a cheap, clean, carbon-free fuel?

In new experiments — conducted on rockets, in microgravity — Canadian and Dutch researchers are looking at ways of boosting the efficiency of burning iron, with a view to turning this abundant material — the fourth most common in the Earth’s crust, about about 5% of its mass — into an alternative energy source.

Iron as a fuel: Iron is abundantly available and cheap. More importantly, the byproduct of burning iron is rust (iron oxide), a solid material that is easy to collect and recycle. Neither burning iron nor converting its oxide back produces any carbon in the process.

Iron has a high energy density: it requires almost the same volume as gasoline to produce the same amount of energy. However, iron has poor specific energy: it’s a lot heavier than gas to produce the same amount of energy. (Think of picking up a jug of gasoline, and then imagine trying to pick up a similar sized chunk of iron.) Therefore, its weight is prohibitive for many applications. Burning iron to run a car isn’t very practical if the iron fuel weighs as much as the car itself.

Neither burning iron nor converting its oxide back produces any carbon in the process.

In its powdered form, however, iron offers more promise as a high-density energy carrier or storage system. Iron-burning furnaces could provide direct heat for industry, home heating, or to generate electricity.

Plus, iron oxide is potentially renewable by reacting with electricity or hydrogen to become iron again (as long as you’ve got a source of clean electricity or green hydrogen). When there’s excess electricity available from renewables like solar and wind, for example, rust could be converted back into iron powder, and then burned on demand to release that energy again.

However, these methods of recycling rust are very energy intensive and inefficient, currently, so improvements to the efficiency of burning iron itself may be crucial to making such a circular system viable.

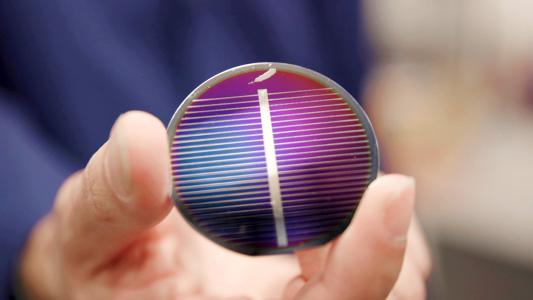

The science of discrete burning: Powdered particles have a high surface area to volume ratio, which means it is easier to ignite them. This is true for metals as well.

Under the right circumstances, powdered iron can burn in a manner known as discrete burning. In its most ideal form, the flame completely consumes one particle before the heat radiating from it combusts other particles in its vicinity. By studying this process, researchers can better understand and model how iron combusts, allowing them to design better iron-burning furnaces.

Presently, the rate at which powdered iron particles burn or how they release heat in different conditions is poorly understood.

Discrete burning is difficult to achieve on Earth. Perfect discrete burning requires a specific particle density and oxygen concentration. When the particles are too close and compacted, the fire jumps to neighboring particles before fully consuming a particle, resulting in a more chaotic and less controlled burn.

Presently, the rate at which powdered iron particles burn or how they release heat in different conditions is poorly understood. This hinders the development of technologies to efficiently utilize iron as a large-scale fuel.

Burning metal in microgravity: In April, the European Space Agency (ESA) launched a suborbital “sounding” rocket, carrying three experimental setups. As the rocket traced its parabolic trajectory through the atmosphere, the experiments got a few minutes in free fall, simulating microgravity.

One of the experiments on this mission studied how iron powder burns in the absence of gravity.

In microgravity, particles float in a more uniformly distributed cloud. This allows researchers to model the flow of iron particles and how a flame propagates through a cloud of iron particles in different oxygen concentrations.

Insights into how flames propagate through iron powder under different conditions could help design much more efficient iron-burning furnaces.

Existing fossil fuel power plants could potentially be retrofitted to run on iron fuel.

Clean and carbon-free energy on Earth: Various businesses are looking at ways to incorporate iron fuels into their processes. In particular, it could serve as a cleaner way to supply industrial heat by burning iron to heat water.

For example, Dutch brewery Swinkels Family Brewers, in collaboration with the Eindhoven University of Technology, switched to iron fuel as the heat source to power its brewing process, accounting for 15 million glasses of beer annually. Dutch startup RIFT is running proof-of-concept iron fuel power plants in Helmond and Arnhem.

As researchers continue to improve the efficiency of burning iron, its applicability will extend to other use cases as well. But is the infrastructure in place for this transition?

Often, the transition to new energy sources is slowed by the need to create new infrastructure to utilize them. Fortunately, this isn’t the case with switching from fossil fuels to iron. Since the ideal temperature to burn iron is similar to that for hydrocarbons, existing fossil fuel power plants could potentially be retrofitted to run on iron fuel.

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].